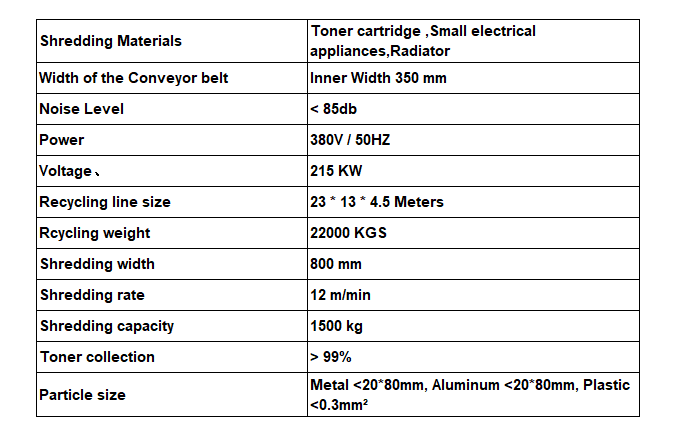

Small size Toner Cartridges Treatment For Recycling

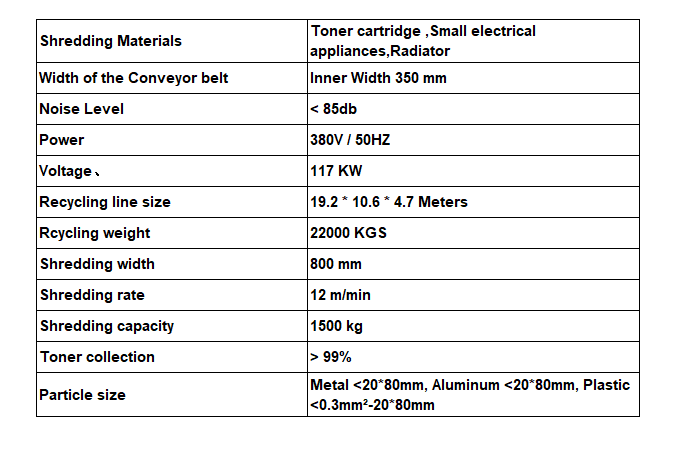

| Categories | RECYCLING LINE |

|---|---|

| Brand | SUPU |

| Model | SPT001 |

| Update Time | Apr 26,2025 |

Toner

Cartridges Treatment For Recycling

The

stable growth of modern office equipment has also brought the corresponding

toner cartridge, toner drum and other consumables at a rate of 30% per year.

These non-degradable consumable materials are discarded as garbage, which not

only causes resource waste, but also increasingly threatens people's living

environment. Toner and toner cartridge carry or spill carbon powder particles

are extremely small, not only pollute the environment, but also harmful to

human respiratory system.

The

toner cartridge consists of plastic, iron, magnetic, aluminums, copper, soft

material and toner, usually with residual toner accounting for 10-20% of toner

weight. Plastic accounts for 41% of the weight of waste gas tone. Recycling of

waste toner cartridge is to separate, recycle and utilize the ferromagnetism,

nonferrous metals, precious metals and organic materials, stabilize or remove

harmful components by means of mechanical and physical methods, and reduce

environmental pollution

ADVANTAGES:

1.Simple collect the toner powder

2.Destroyed safety with explosion protection

3.Seperate ferrous metal and non-ferrous metals and

plastics

4.Only need two person to control this recycling line

5.Toner collection to avoid of explode and pollution when in the shredding.

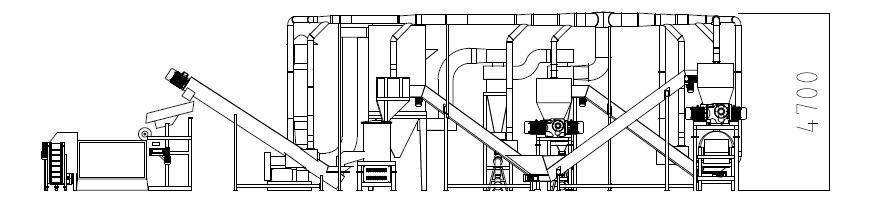

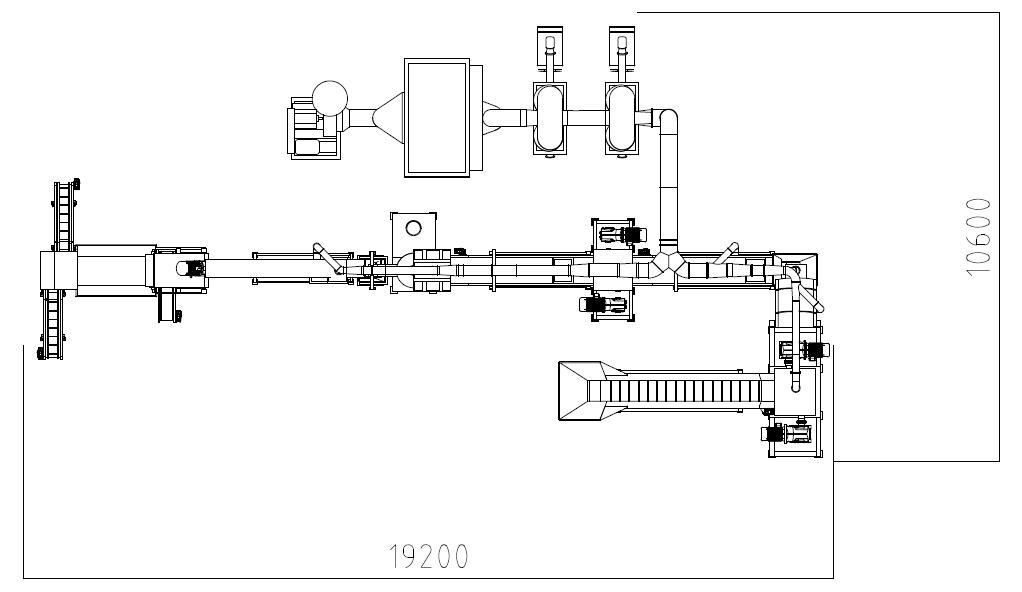

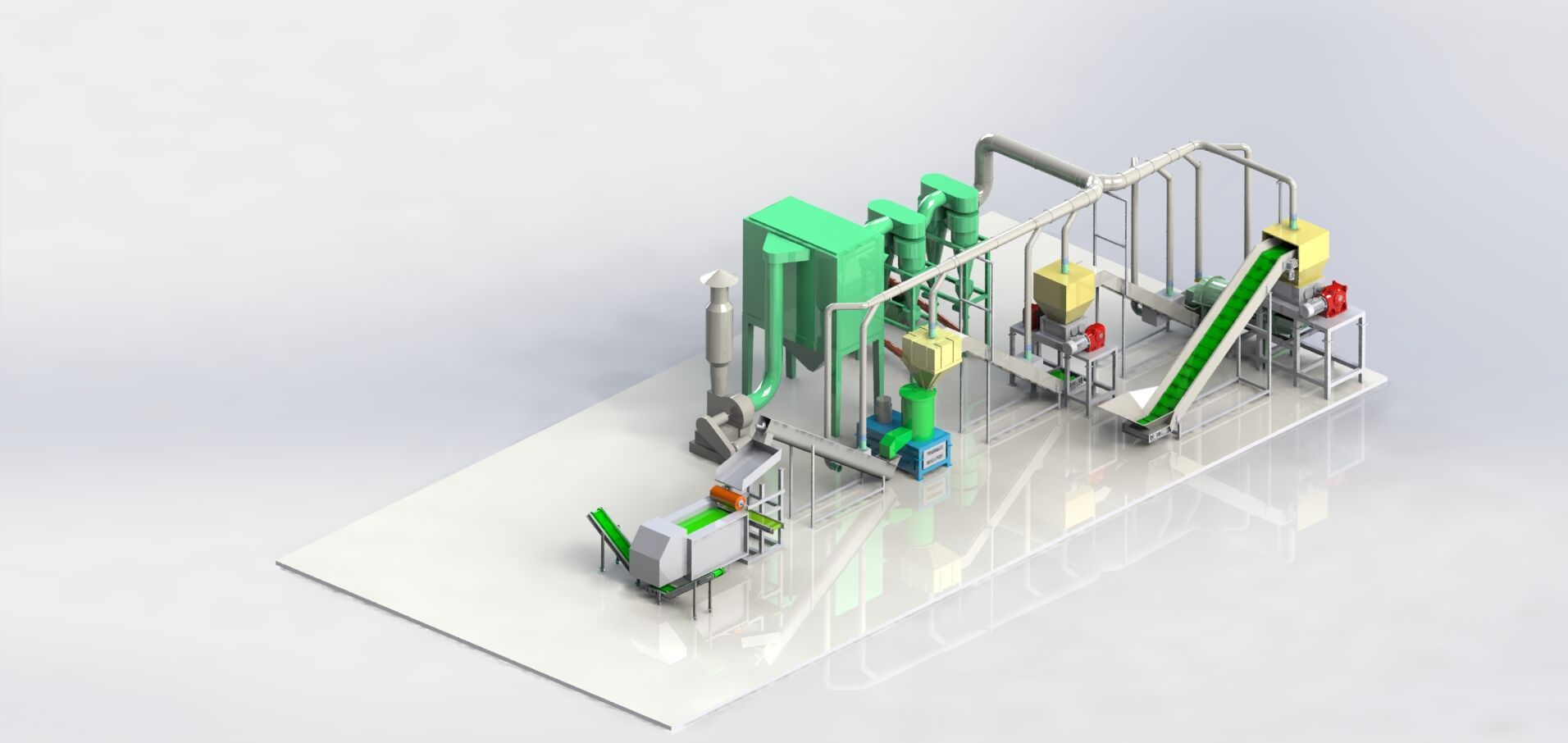

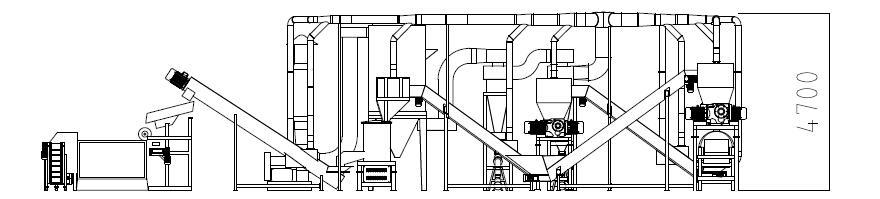

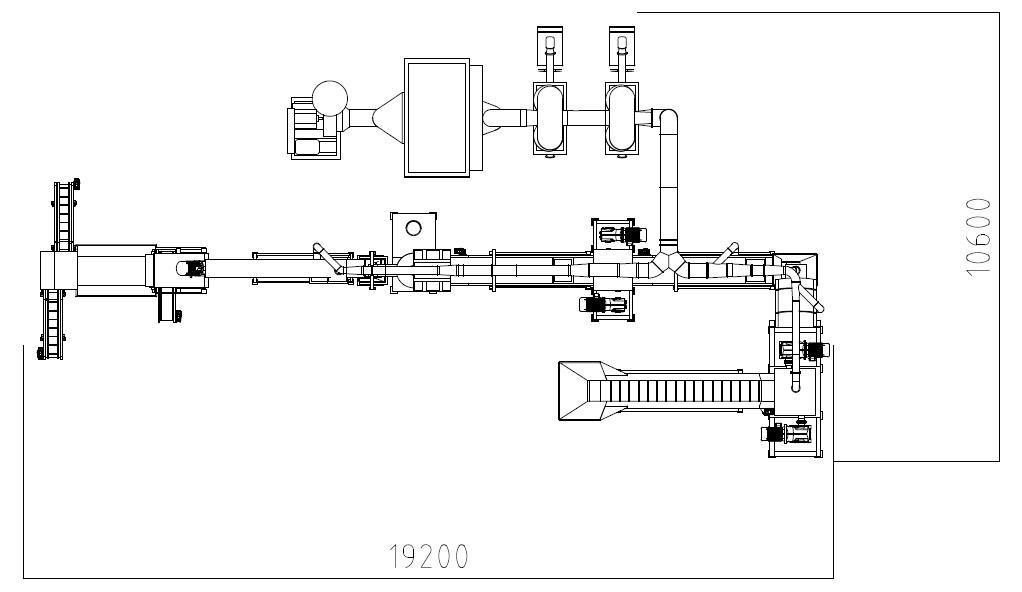

1.

Feeding the toner Cartridges to the first stage shredder with variable

frequency feed conveyor belt, double shafts and double motor drive can meet the

requirements of continuous shredding of materials, after the shredding output

size is 30mm*150mm;

2.

The roller screen is used to shake and screen out materials and toner. The

toner duster collection can remove 95% of toner

3.

Drive the conveyor belt to send the toner cartridge fragments to the secondary shredder,

double shafts and double motor drive can meet the requirements of material

continuous grinding and make the output size is 30mm*100mm, and the sealed

suction pipe continues to remove the remaining toner;

4.

The conveyor belt shall send the toner cartridge fragments to the three-stage

compound crusher with the output size of 20mm*80mm, and the sealed dust suction

pipe shall clear up to 99.9% carbon powder and dust;

5.

Iron removal screen separates iron and delivers it to the discharge bin

6.

The eddy-current sorting system separates aluminum and plastics and delivers

them to their respective discharge bins

- Tel

- *Title

- *Content